Rice, a dietary staple for millions worldwide, is a cornerstone of Pakistan’s agriculture and economy. With fertile lands and a favourable climate, the country has emerged as one of the largest producers and exporters of rice globally. Among the various elements that drive the rice industry, rice mills in Pakistan hold a critical place.

These mills bridge the gap between paddy harvested from the fields and the polished grains that reach our tables. They play a pivotal role in ensuring the production of high-quality rice suitable for domestic consumption and international markets. In this blog, Graana.com delves deep into the world of rice mills in Pakistan, exploring their significance, challenges, and future prospects in detail.

Rice Industry in Pakistan

Let’s shed some light on the rice mills in Pakistan:

Key Rice-Producing Regions

Pakistan’s geography is particularly suited for rice cultivation, with expansive plains and an intricate network of irrigation canals. The following are the key regions that contribute to the country’s thriving rice industry:

- Punjab: Often referred to as the breadbasket of Pakistan, Punjab is celebrated for producing aromatic Basmati rice, a variety that commands high prices in international markets due to its distinct flavour and texture.

- Sindh: The second-largest producer of rice in the country, Sindh is known for cultivating IRRI and hybrid varieties that are both high-yield and suitable for diverse climatic conditions.

- Balochistan and Khyber Pakhtunkhwa: While these regions contribute relatively less to the overall production, their rice varieties are recognised for their unique quality standards and are often used in niche markets.

Types of Rice Produced

Pakistan’s diverse agricultural practices allow for the cultivation of multiple rice types, each catering to specific markets and culinary needs:

- Basmati Rice: Synonymous with premium quality, Basmati rice is long-grained, aromatic, and soft-textured. It is a staple for celebratory dishes and has immense demand globally.

- IRRI Rice: Characterised by shorter grains, IRRI rice is mainly grown in Sindh. It’s a versatile variety suitable for everyday meals and bulk exports.

- Hybrid Rice: Developed to meet the growing demands of both domestic and international markets, hybrid rice varieties are high-yield and cost-efficient.

Economic Significance

The rice industry is not just an agricultural pursuit but a major economic pillar for Pakistan. Contributing significantly to the national GDP, rice is among the country’s top three exports. Pakistan accounts for over 8% of the global rice trade, and the industry supports millions of livelihoods, from farmers to mill operators and exporters.

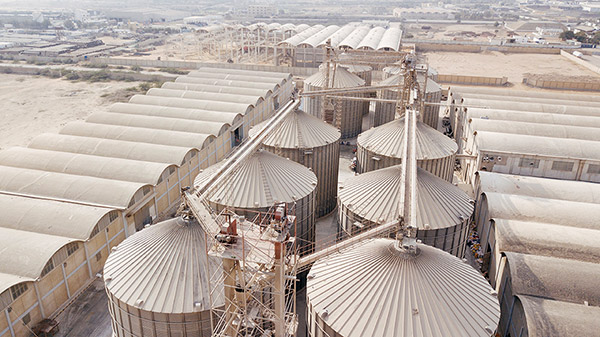

Role of Rice Mills

Rice mills in Pakistan are the linchpin of the rice supply chain, transforming raw paddy into polished grains ready for consumption. Without these facilities, it would be impossible to maintain the quality and quantity demanded by both local and international markets. The various processes performed in rice mills include:

- Cleaning: The initial step involves removing impurities such as stones, dust, and husk from the raw paddy, ensuring a clean base product.

- Dehusking: This process removes the tough outer husk from the paddy, resulting in brown rice.

- Milling: Brown rice is further processed to remove the bran layer, producing white, polished rice.

- Polishing and Grading: To enhance market appeal, rice grains are polished to give them a lustrous finish and graded according to size, shape, and quality.

- Packaging: Once processed, the rice is carefully packaged to retain its freshness and quality during transportation and storage.

Modern rice mills in Pakistan have adopted advanced technologies, enabling them to improve efficiency, reduce waste, and ensure consistency in quality. This evolution has allowed Pakistani rice to compete effectively in global markets.

Major Rice Mills in Pakistan

Pakistan boasts a range of rice mills, from small-scale units in rural areas to large, state-of-the-art facilities. Below is an overview of some of the most prominent rice mills in Pakistan that have set benchmarks in the industry:

Matco Foods

With decades of experience, Matco Foods has established itself as a leader in the rice export market. Specialising in premium Basmati rice, the company exports to over 60 countries. Its commitment to quality assurance and innovation has earned it global recognition.

Guard Rice Mills

A household name in Pakistan, Guard Rice Mills is known for its high-quality Basmati rice. The company’s robust processing capabilities and extensive distribution network make it a trusted brand both locally and internationally. This mill is located in Raiwind, Lahore.

Meskay & Femtee Trading Company

This company operates some of the most advanced rice mills in the country. Their focus on innovation and diversification allows them to cater to a broad spectrum of markets, offering a range of rice products.

Galaxy Rice Mills

Located in the heart of Punjab, Galaxy Rice Mills combines traditional methods with modern technology to produce top-notch Basmati and non-Basmati rice. Their products are a staple in households and restaurants alike.

Al-Barkat Rice Mills

A name synonymous with quality, Al-Barkat Rice Mills excels in meeting international food safety standards. Their rigorous quality control measures ensure that only the best rice reaches the market.

Rice Export Potential

Pakistan’s rice export sector is a vital contributor to the country’s economy. The following factors highlight its potential:

- Key Markets: Pakistani rice is highly sought after in regions like the Middle East, where Basmati rice is a staple, and in Europe and Africa, where large quantities of both premium and bulk varieties are imported.

- Competitive Advantage: The aromatic and long-grain Basmati rice gives Pakistan a unique edge over competitors like India, Vietnam, and Thailand.

- Export Challenges: Despite its strengths, the sector faces hurdles such as inconsistent quality, high production costs, and competition from other exporters. These challenges necessitate improvements in infrastructure and milling processes.

Technological Advancements in Rice Milling

The integration of technology has significantly enhanced the operational efficiency of rice mills in Pakistan. Notable advancements include:

- Automated Sorting Machines: These machines identify and remove defective grains, ensuring uniform quality.

- Energy-Efficient Systems: Modern mills are designed to consume less energy, reducing operational costs and environmental impact.

- Parboiling Technology: This process improves the nutritional profile and cooking quality of rice, making it more appealing to health-conscious consumers.

By adopting these technologies, rice mills can cater to high-value markets and maintain their competitive edge.

Challenges Faced by Rice Mills in Pakistan

While rice mills play a critical role in the industry, they are not without challenges. These include:

- Energy Deficits: Frequent power outages disrupt operations, leading to delays and increased costs.

Infrastructure Limitations: Rural mills often lack access to modern facilities, which hampers their ability to produce high-quality rice. - Climate Variability: Unpredictable weather patterns impact the quality and quantity of rice harvests, putting additional strain on mills.

- Global Competition: Competing with countries like India and Vietnam, which have lower production costs and better technology, remains a significant hurdle.

- Addressing these issues requires coordinated efforts from the government, private sector, and industry stakeholders.

Future of Rice Mills in Pakistan

The future of rice mills in Pakistan is bright, provided the industry takes proactive steps to adapt to changing market dynamics. Key opportunities include:

- Sustainable Practices: Implementing eco-friendly technologies to reduce waste and energy consumption can improve efficiency and environmental sustainability.

- Government Support: Policies and incentives aimed at modernising the rice milling sector can spur growth and innovation.

- Value-Added Products: Expanding into related markets, such as rice flour, ready-to-cook meals, and puffed rice, can diversify revenue streams.

Conclusion

Rice mills in Pakistan are the unsung heroes of Pakistan’s agricultural landscape. Their ability to process and refine raw paddy into high-quality rice ensures the country’s position as a global leader in the rice trade. However, to realise their full potential, it is imperative to address the existing challenges and invest in modernisation.

With the right strategies and a focus on sustainability, rice mills in Pakistan can continue to thrive, benefiting millions and contributing significantly to the nation’s prosperity. If you want to know more about sugar mills in Pakistan, visit the graana blog.